- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Shanghai, China

LC, T/T

FOB, CFR, CIF, EXW

CE, ISO, UL, QS, GMP

1 Year

Peak season lead time: 3-6 months, Off season lead time: 1-3 months

| Availability: | |

|---|---|

Product Description

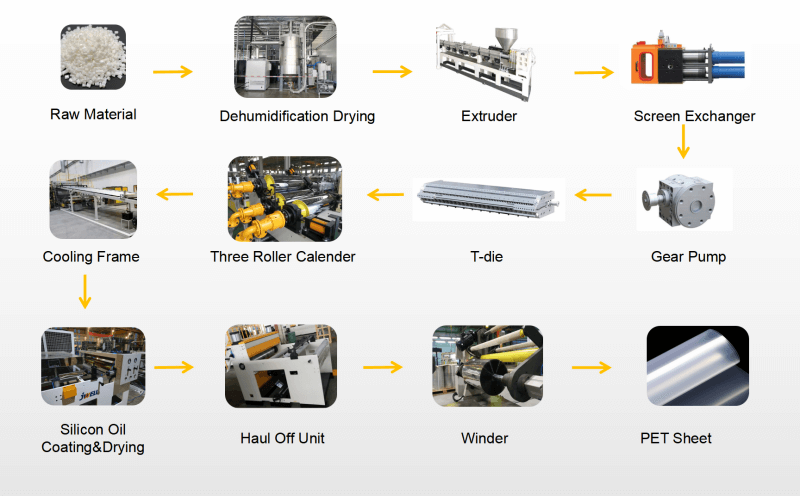

JWELL PET/PLA sheet extrusion machine is a manufacturing system used to produce high-quality PET/PLA sheets, which are widely used in packaging, printing, and advertising industries. The process involves feeding resin into an extruder, where it is melted and forced through a T-die to form a thin sheet. This sheet is then cooled and solidified through rollers or calendering, and it is trimmed to the desired size before being wound into large coils for further use. As the leading manufacturer of plastic extrusion and recycling lines in China, with over 40 years of experience, JWELL provides customers with professional and complete solutions in the field of plastic extrusion.

| Extruder Model | JWS100-800 | JWS120-1000 | JWS130-1000 | JWS150-1200 | JWS160-1200 |

| Product Thickness(mm) | 0.2-1.5 | 0.2-1.5 | 0.2-1.5 | 0.2-1.5 | 0.2-1.5 |

| Main Motor Power(kw) | 110 | 132 | 160 | 220 | 315 |

| Max Capacity (kg/h) | 300 | 500 | 600 | 800 | 1000 |

PET sheet (Polyethylene Terephthalate sheet) is a type of plastic material made from the polymerization of terephthalic acid and ethylene glycol. It is a clear, rigid, and durable plastic that has a wide range of applications due to its excellent properties. PET is commonly used for producing sheets that are then fabricated into various products.

Packaging: PET sheets are commonly used in packaging applications, including food packaging, blister packs, and thermoforming.

Signs and Displays: Due to their clarity and durability, PET sheets are used in signage and display manufacturing.

Automotive: PET sheets are used in automotive interiors, particularly in parts like dashboards, door panels, and trims.

Electronics: PET is used in the electronics industry for protective covers and insulation materials.

PLA Sheet (Polylactic Acid Sheet) is a type of biodegradable plastic material made from renewable resources, such as corn starch or sugarcane.

Packaging: PLA sheets are widely used for food packaging, such as trays, clamshells, and cups, due to their clarity and biodegradability.

Consumer Goods: They can be used to make disposable cutlery, plates, and other single-use items.

Medical Devices: PLA is also used in medical applications, such as implants and sutures, due to its biocompatibility.

3D Printing: PLA is a popular material for 3D printing because it is easy to work with and has a low melting point.

JWELL PET PLA Sheet Extrusion Line.pdf

JWELL PET PLA Sheet Extrusion Line.pdf

Jwell Machinery is a leading Chinese manufacturer specializing in the production of extrusion machinery, particularly for the plastic processing industry. Founded in 1997, Jwell has become one of the largest and most well-known manufacturers of plastic extrusion equipment in China and is recognized globally for its high-quality products.

· Single-Screw & Twin-Screw Extruders for different production needs.

· Dehumidification and Crystallization-Free Technology for energy savings.

· Enables multi-layer sheets for enhanced properties.

· Suitable for virgin, recycled PET/PLA, and PETG materials.

· Intelligent temperature control for uniform thickness.

· High-precision calendering system for improved surface quality.

· Tailor-made solutions for various packaging, thermoforming, and industrial applications.

· Fully automated production lines for increased efficiency and reduced labor costs.

· Supports 100% recycled PET material to promote sustainability.

· Low energy consumption with optimized extrusion technology.

· End-to-end services, including installation, training, and after-sales support.

· Maintenance assistance to ensure smooth operations.

· JWELL has a proven track record of delivering extrusion lines to clients worldwide, ensuring reliable and efficient solutions for PET/PLA sheet production.

FAQ

Certificates And Patents

Quick Links